We Use Cookies

We use cookies to ensure our website functions properly, provide customer support, and enhance your browsing experience. By continuing to use this website, you consent to our use of cookies.please refer to ourPrivacy Policy

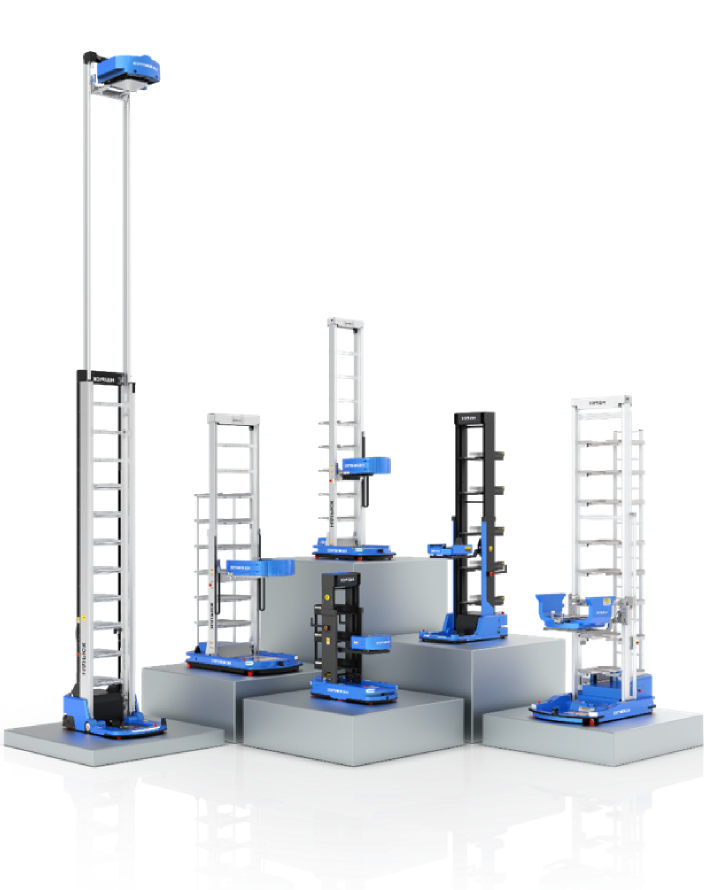

High speed operation

High speed operation Quick reversal

Quick reversal Precise positioning

Precise positioning Maintenance free

Maintenance free

Provided according to user needs

Provided according to user needs Compact structure, precise control

Compact structure, precise control Multi-level permission management function

Multi-level permission management function Has stronger bearing capacity

Has stronger bearing capacity Has better security protection functions

Has better security protection functions Runs more smoothly, faster and safer

Runs more smoothly, faster and safer

High flexibility

High flexibility High cost performance

High cost performance Perform automated management

Perform automated management Realize intelligent transportation

Realize intelligent transportation Picking, and sorting

Picking, and sorting Has the advantages of high efficiency

Has the advantages of high efficiency